Bow Spring Centralizers

Hinged Non-Welded Bow Spring Centralizer

Hinged Non-Welded Bow Spring Centralizers is a reliable and versatile oilfield tool that ensures proper wellbore centralization and improves cementing performance. All products fulfill the requirements as per API 10D latest Edition.

Advantages:-

- Ease of installation.

- Reduced drag

- Improve cementing

- Cost Effective

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.

Hinged Welded Bow Spring Centralizer

Hinged Welded Spring Bow Centralizers are high quality welded products, which meet or exceed API 10D specifications. This design allows the centralizer to expand and contract to fit the wellbore diameter while providing continuous contact between the casing and the wellbore. All products fulfill the requirements as per API 10D latest Edition.

Advantages:-

- Enhanced stability

- Increased standoff

- Durability

- Improved flow

Available in 3-1/2” to 30” sizes.

Any special sizes or combinations can be made available on request.

Hinged Semi-Rigid Non Welded Bow Spring Centralizer

The Hinged semi-rigid non-welded bow spring centralizer is a reliable and versatile oilfield tool that ensures proper wellbore centralization and improves cementing performance. It is suitable for use in various wellbore conditions, including deviated, horizontal, or highly tortuous wells. All products fulfill the requirements as per API 10D latest Edition.

Advantages:-

- Improved centralization

- Reduced Drag

- Restoring force exceeds API 10 D

- Improved cementing

- Cost effectiveness

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.

Hinged Semi-Rigid Welded Bow Spring Centralizer

The Hinged semi-rigid welded bow spring centralizer is a robust and effective oilfield tool that ensures proper wellbore centralization and improves cementing performance in a wide range of applications. All products fulfill the requirements as per API 10D latest Edition.

Advantages:-

- Improved centralization

- Enhanced stablity

- Restoring force exceeds API 10 D

- Improved cementing

- Durability

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.

Hinged Non Welded Positive Rigid Centralizer

The term “positive” refers to the fact that the centralizer maintains a constant standoff between the casing and the wellbore, which helps to ensure efficient cementing and reduces the risk of differential sticking. The term “rigid” indicates that the centralizer maintains its shape and stiffness under load, and is not prone to deformation or collapse.

The use of a non-welded design eliminates the risk of cracking or failure due to welding defects or high-temperature exposure. Hinged centralizers are typically used in deviated or horizontal wellbores, where the risk of differential sticking is higher and the casing is more likely to come into contact with the wellbore wall . All products fulfill the requirements as per API 10TR5.

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.

Hinged Welded Positive Rigid Centralizer

A hinged welded positive rigid centralizer is a similar device to the hinged non-welded positive rigid centralizer, but with the addition of welded connections between the hinges and the collars. This design provides additional strength and durability to the centralizer, as the welded connections are able to withstand higher loads and stresses than non-welded connections. All products fulfill the requirements as per API 10TR5.

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.

New Generation Bow Spring Centralizer

The use of a New Generation Bow Spring design eliminates the need for hinges and welded connections, simplifying the design and reducing the risk of failure or cracking. New Generation Bow Spring centralizers can be designed to provide a positive stop against the wellbore wall, preventing the casing from contacting the formation and reducing the risk of differential sticking. They can also be designed to provide a range of standoff distances, allowing for flexibility in wellbore design and cementing operations.

Overall, New Generation centralizers offer a simple, reliable, and cost-effective solution for casing centralization in oil and gas drilling operations. Their design and material selection can be tailored to meet the specific requirements of the wellbore and the drilling operation, making them a versatile option for a wide range of applications. All products fulfill the requirements as per API 10D latest Edition.

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.

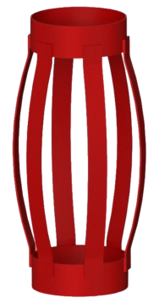

Slip On Welded Bow Spring Centralizer

The centralizer consists of a set of metal bows or springs that are welded to a steel collar, forming a cylindrical shape. The centralizer can be easily slipped onto the casing before it is lowered into the wellbore.

The bow springs are designed to flex and expand outwards as the casing is lowered into the wellbore, providing a positive stop against the wellbore wall and centering the casing. This design helps to ensure efficient cementing and reduce the risk of differential sticking.The welded construction provides additional strength and durability to the centralizer, allowing it to withstand higher loads and stresses than non-welded designs. All products fulfill the requirements as per API 10D latest Edition.

Available in 4-1/2” to 20” sizes.

Any special sizes or combinations can be made available on request.